Tray system

Removable compartment, up to 8 SKUs per tray, shippable, reusable, palletize-able

Cart & AMR

A sorted batch of trays, mobile transport, anytime anywhere, eliminating sorters and conveyors

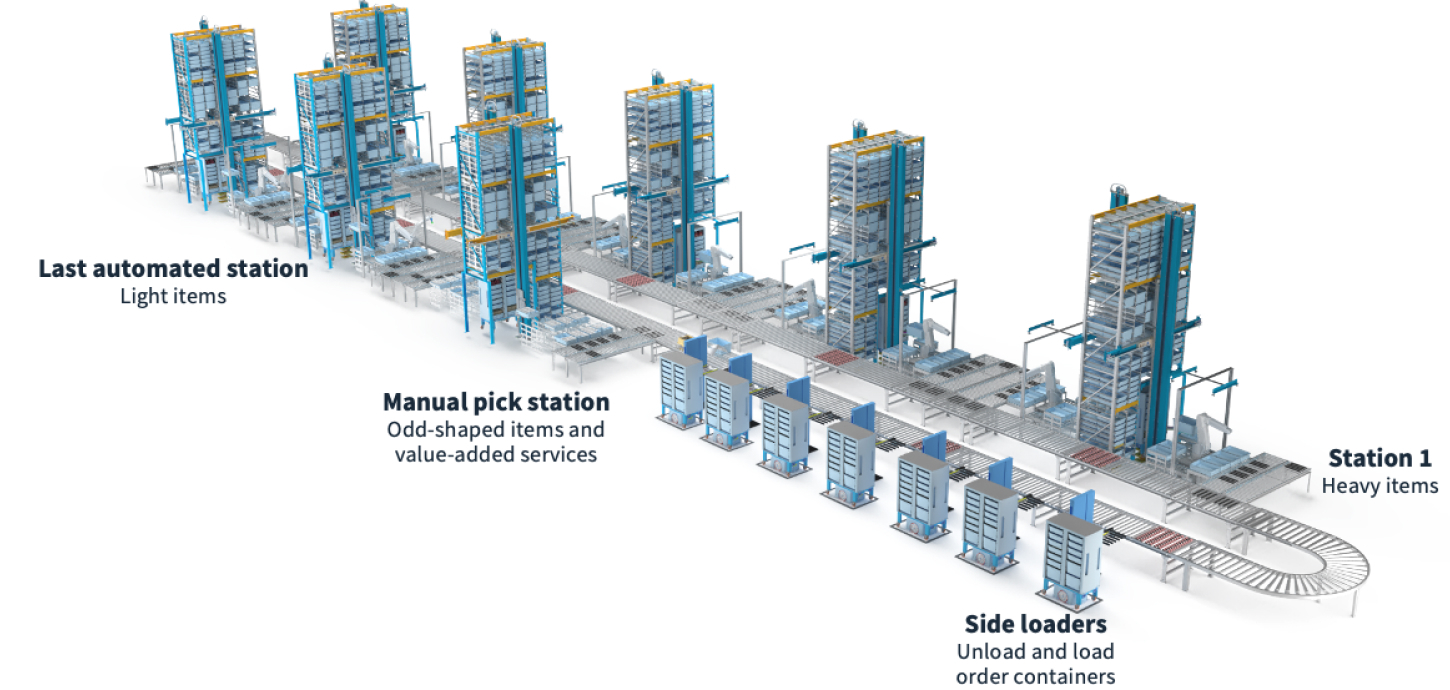

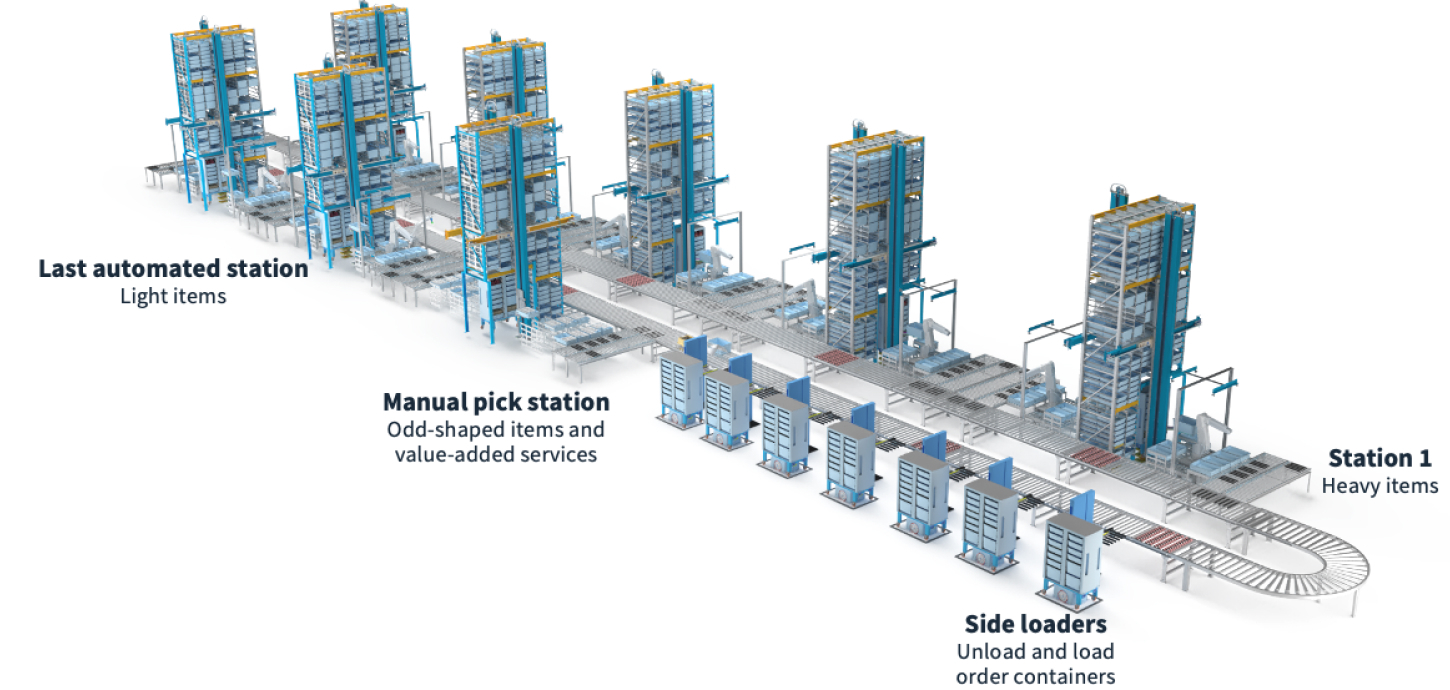

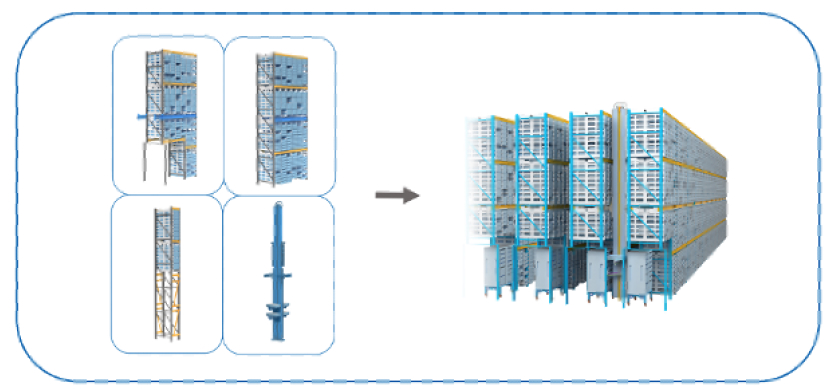

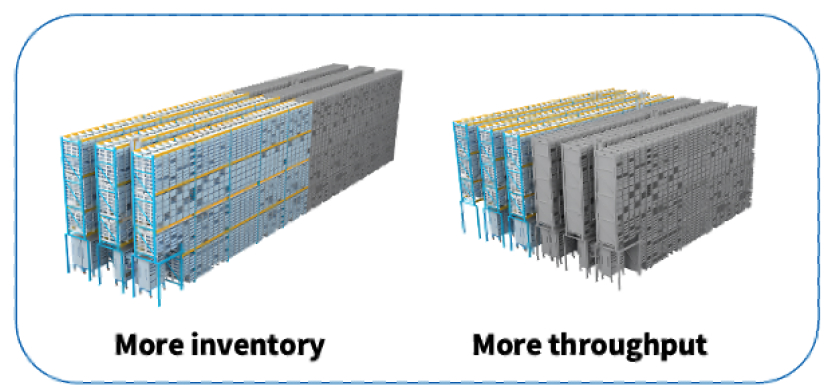

Tray storage

Dense, shelf-less storage (RAM), high-speed extractor, sorting and storage in one process

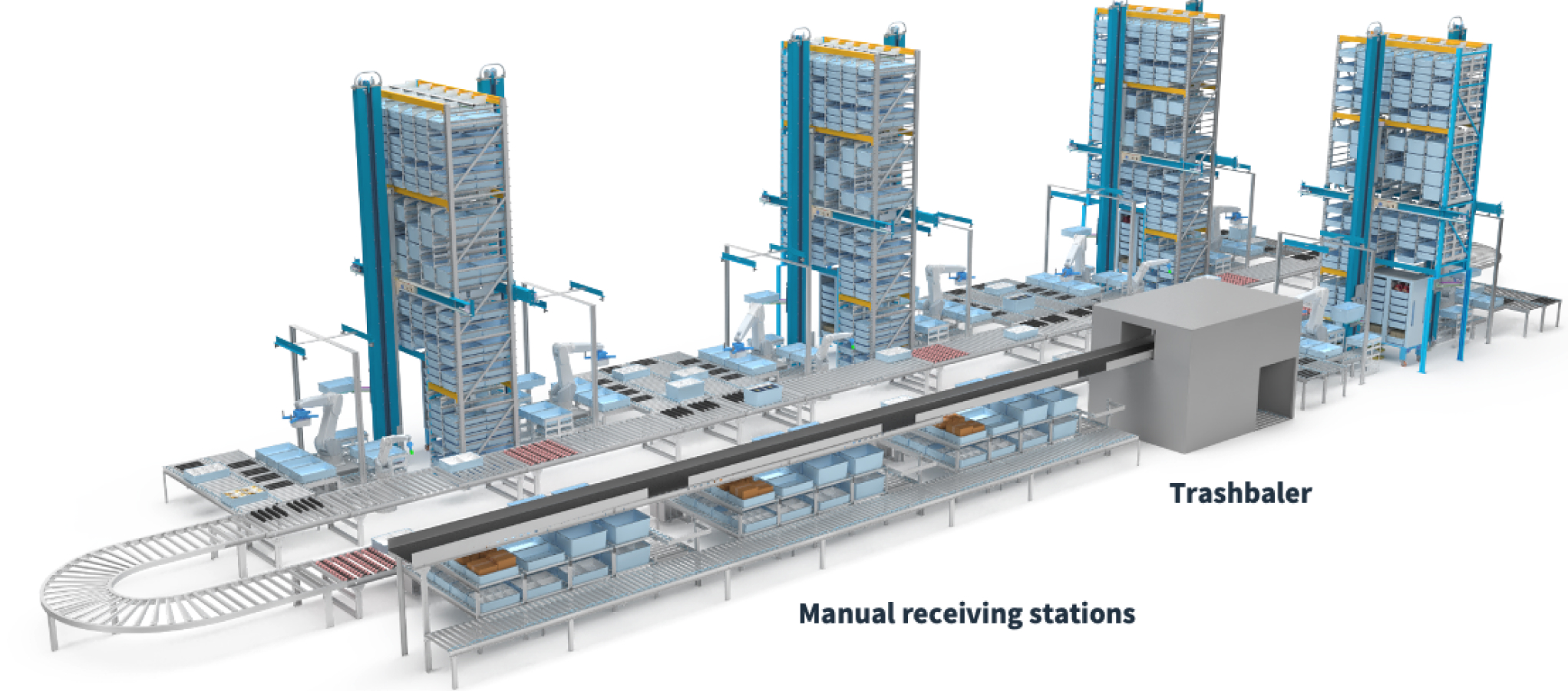

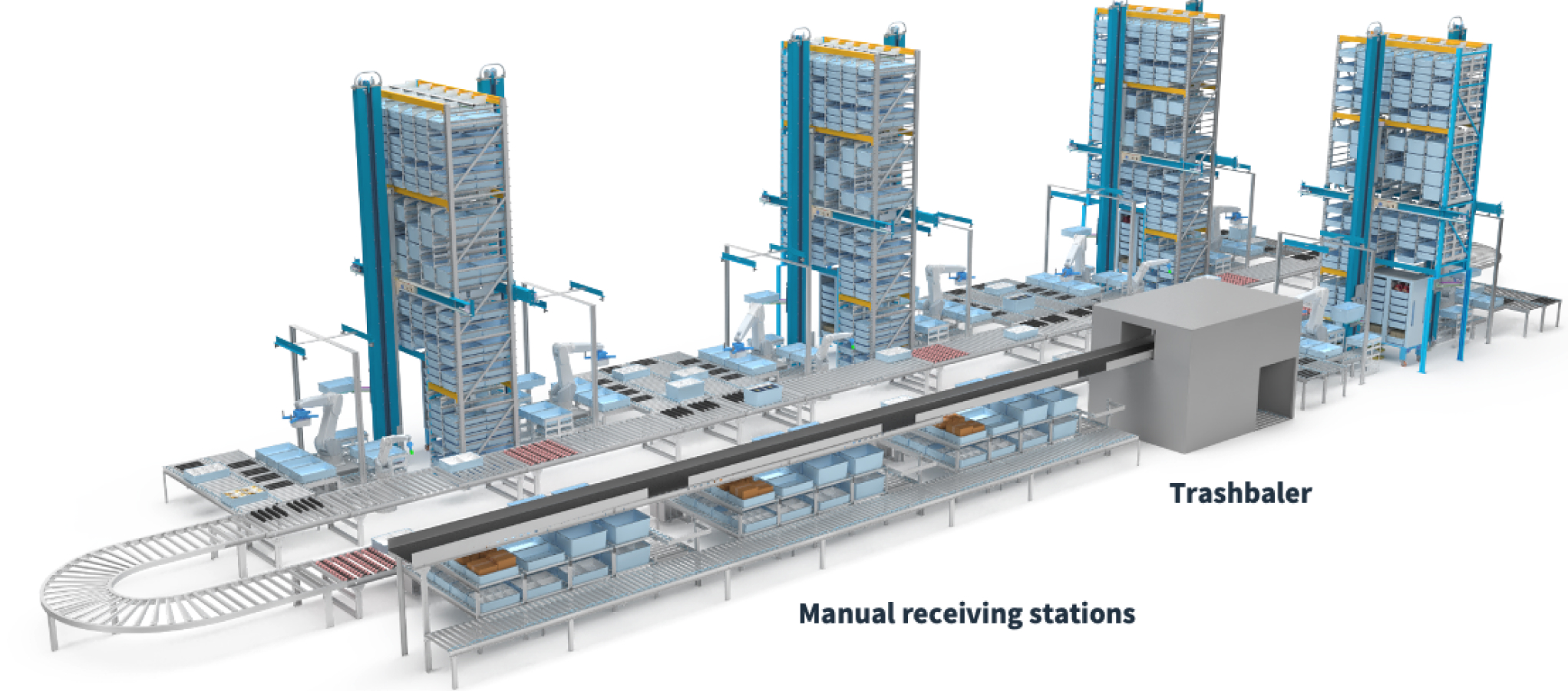

Receiving and Pack

Re-use of the core technology in the tray storage module, high capacity buffer (cache)